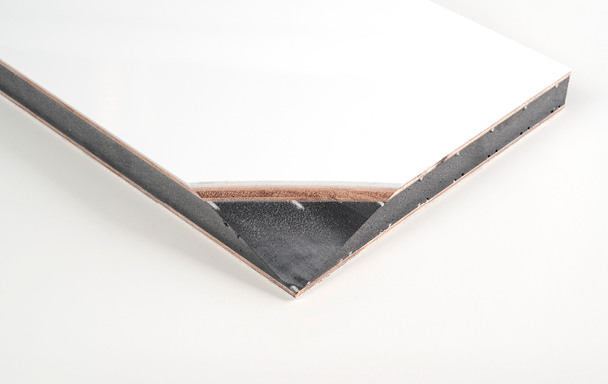

Construction of the sandwich panels

All sandwich panels and modular systems are fully customized, based on the wishes of our customers. With our wide range of high-quality raw materials, we offer complete flexibility in size, weight, durability, complexity, and mechanical properties.

Surface claddings

Standard materials for the interior and exterior cladding of the panels.

For a visually smooth surface of the panels, you can choose between the high-quality Topcoat or the budget-friendly Gelcoat. Both variants can be applied in various widths, with thicknesses ranging from 1.2mm to 3mm. All rolls come in the standard color RAL9016. Specific colors can also be ordered upon request.

For improved mechanical properties of the panels, you can choose for the high-quality Topcoat Woven Roving or the budget-friendly Gelcoat Woven Roving. Both variants are available in various widths, with thicknesses ranging from 1.1mm to 3mm. All rolls come in the standard color RAL9016. Specific colors can also be ordered upon request.

Core materials

Standard types of foam that can be used as core material in the panels.

With its excellent mechanical properties and temperature resistance up to over 150 degrees, the sustainable BaerCore is the perfect solution for high-quality panels. Various BaerCore variants are available with densities ranging from 50 kg/m³ to 75 kg/m³.

Lightweight, waterproof, and cost-effective. With its good mechanical properties, XPS foam provides the ultimate balance between price and quality. Various XPS variants are available with densities ranging from 33 kg/m³ to 45 kg/m³.

Reinforcements

Standard materials for local reinforcements in the panels.

Due to its high mechanical properties and water resistance, BaerCore+ rigid foam is the perfect solution for edge finishing around the panels and cutouts. Like the standard BaerCore, the ‘plus’ variant is a sustainable product with high temperature resistance. Various BaerCore+ variants are available with densities ranging from 195 kg/m³ to 250 kg/m³.

For areas where screws need to be installed in the panel, BaerComposite offers the perfect solution with a screw withdrawal resistance of 12.5 MPa. BaerComposite has a density of 600 kg/m³.

Plates

Standard plate materials that can be added as an extra layer.

The traditional solution for enhancing the stiffness, compressive strength, and screwability of the panel. The plywood plates can be incorporated fully or locally into the panels. The wood types used include birch, okoume, poplar, and Indonesian hardwood. All plates have water-resistant adhesive and can be applied in any desired thickness.

A lightweight alternative to plywood is fiber with a thickness of 2.7mm. Incorporating these boards fully or locally into the panels improves the screwability and compressive strength of the panel.

Inlays

Standard profiles that can be incorporated into the panels.

Standard or custom-made aluminum profiles, plates, and welded frames can be incorporated into the panels upon request.

Standard or custom-made steel profiles, plates, and welded frames can be incorporated into the panels upon request.